Creativity

Style, CAD, Product development, production, sales office, logistics and warehousing are all elements that combine to produce a final result of excellence.

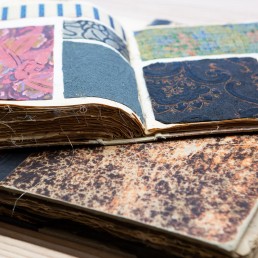

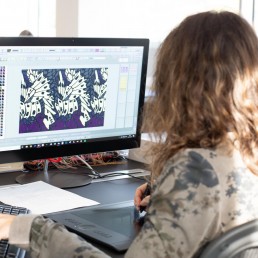

The Style office and the CAD department lie at the heart of the creative phase, performing research and development activities that are meticulous, in-depth and non-stop. For specialists of this segment, there are sources of inspiration everywhere: history books, art exhibitions, photographs, readings, encounters with customers and suppliers, not forgetting the archive, a true heritage gathered during decades of activity. All this helps to create a particularly fertile substratum of ideas, options and suggestions.

One part artisan, one part artist, and certainly a large part dreamer, the DNA of those responsible for style at Tessitura Puricelli helps them “industrialize” the initial ideas, making them possible to produce.

The actual production itself is in fact the result of a careful preparatory activity of research and experimentation whereas the company’s commitment to research and development continues incessantly, creating over 4,000 new samples every year.

Production

The large stock of a wide variety of products, which seems worlds away from runways, designers and successful brands, is the first stage of the production activity of Tessitura Puricelli, which considers rapid response times a key value for ensuring the success of the company and its customers.

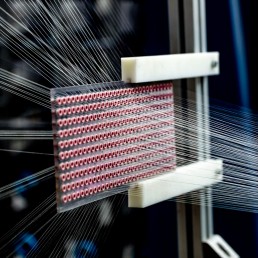

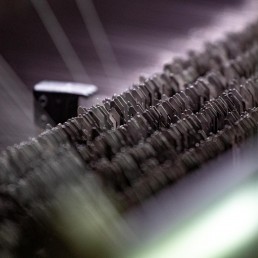

The production draws from an immense variety of fibers and yarns, in a myriad of different shades, relying on a warping and a specific weaving department, with shafts and jacquard looms.

Modern, versatile machines that transform all the previous creative phases into real products you can see and feel. The quality control on the finished products completes the production flow, a process that is all strictly Made in Italy. Or in fact, Made in Como.

Production

The large stock of a wide variety of products, which seems worlds away from runways, designers and successful brands, is the first stage of the production activity of Tessitura Puricelli, which considers rapid response times a key value for ensuring the success of the company and its customers.

The production draws from an immense variety of fibers and yarns, in a myriad of different shades, relying on a warping and a specific weaving department, with shafts and jacquard looms.

Modern, versatile machines that transform all the previous creative phases into real products you can see and feel. The quality control on the finished products completes the production flow, a process that is all strictly Made in Italy. Or in fact, Made in Como.

Eco-sustainability

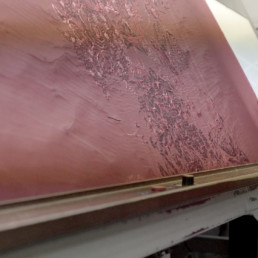

Tessitura Puricelli has been closely following the evolution of the problems related to the use of chemical substances in the textile sector for many years.

Although the company itself does not perform any treatments or processes involving the use of chemical substances, on this topic and based on the statements obtained from our suppliers of raw materials and/or services associated with our fabric production, we are pleased to confirm that our products do not contain nor are treated with any of the substances deemed “extremely worrying” and listed as SVHC – Substances of Very High Concern.

Regarding the ZDHC requirements – Zero Discharge of Hazardous Chemicals – , a system has been set up to regularly analyze and monitor the chemical products that can be contained in the raw materials used when processing the fabrics, such as finishes, scouring agents, etc., even if they are not used directly by this company.

This system aims to confirm the accuracy of the statements obtained before the supply, in order to provide the clientele with information that is as complete as possible. A “controlled production chain” is therefore an additional mark of the focus on the customer that we hope defines us.

Since September 2021, we have had GOTS and GRS certificates. In May 2022, we also obtained the FSC certificate.